Design and development

Thermal forming mould for medical packaging is generally aluminum alloy mould.

In the medical device industry, we generally choose aluminum alloy die, and its processing technology is made of aluminum ingots through mechanical processing (lathe, milling machine, CNC, etc.). The aluminum die has good quality, fast heat dissipation, high precision, smooth and durable surface, and has the advantages of saving time and electricity, high production efficiency and very low scrap rate, but the price is relatively high. What's more, the aluminum mold is superior to other molds in its bacteriostatic ability, which is the best among several molds. The carrier of bacteria is dust. There will be more or less dust in other molds. The copper mold will even generate a lot of mold on the basis of verdigris. Only alloy aluminum mold is relatively safe.

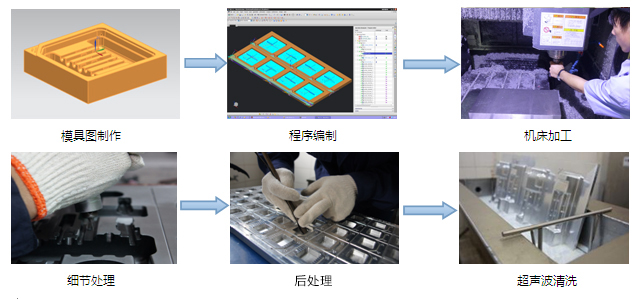

Blister aluminum mold process

售前咨询热线

QQ咨询 sales

QQ咨询 sales

QQ咨询 sales

QQ咨询 sales